AWGSim - Introduction

AWGSim is a modular, real-time simulator of Atmospheric Water Generators (AWGs) based on the Vapour Compression Refrigeration Cycle (VCRC) technology. AWGSim is implemented as a stand-alone Java application in order to offer the maximum compatibility across different operating systems/environments.

Features

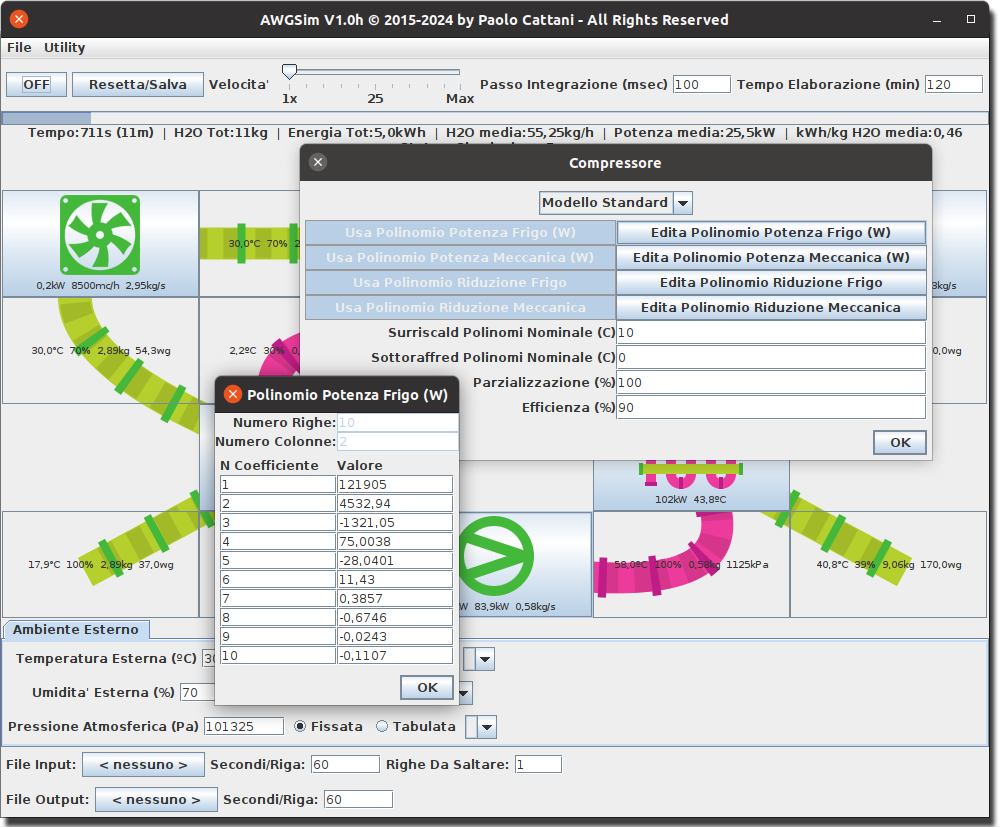

Modular Design: any component of an AWG machine is separately simulated as a stand-alone class with its own interface and functionalities. The system is "assembled" by AWGSim by reading a configuration .xls file that contains the description of each component and how those components should be linked together. That technology allows AWGSim to represents many different AWG machines and not just some pre-configured systems, because the user, by editing/changing the corresponding .xls file, can modify the actual configuration of the simulated machine.

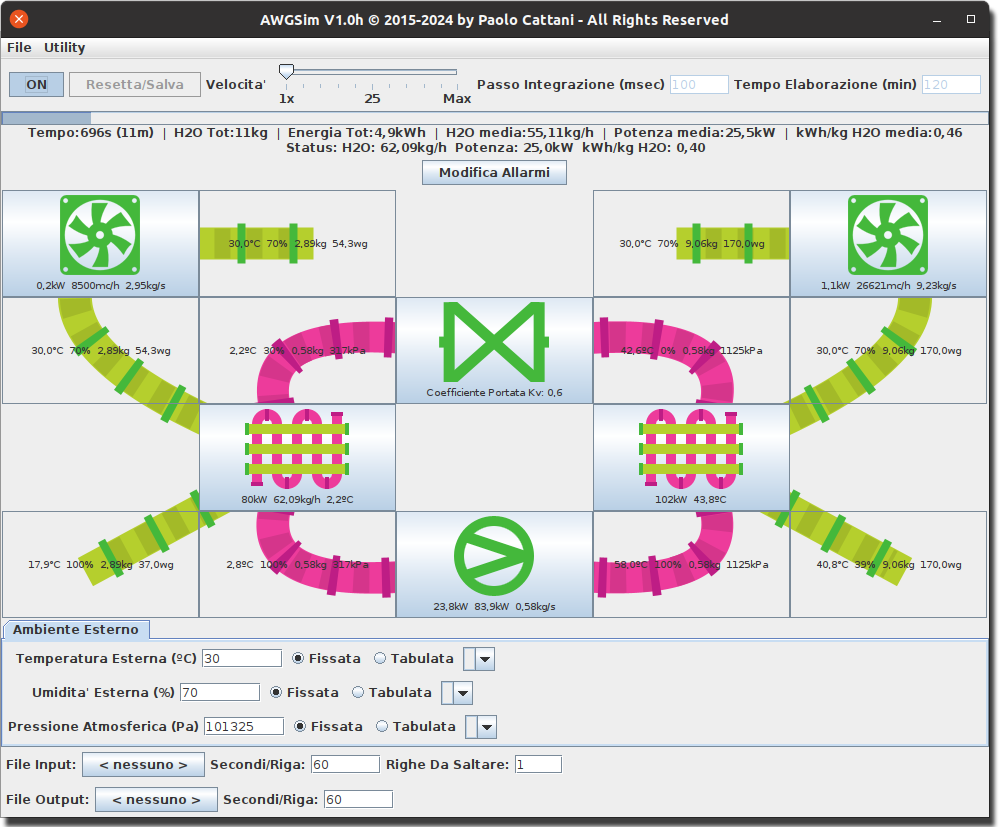

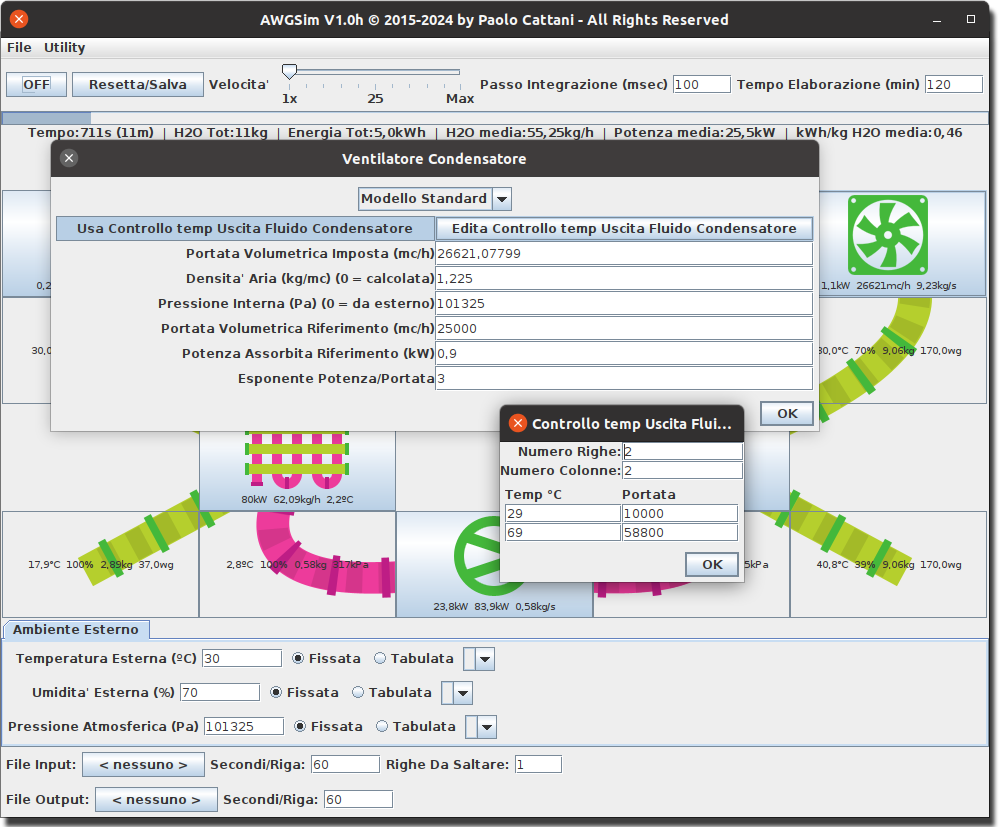

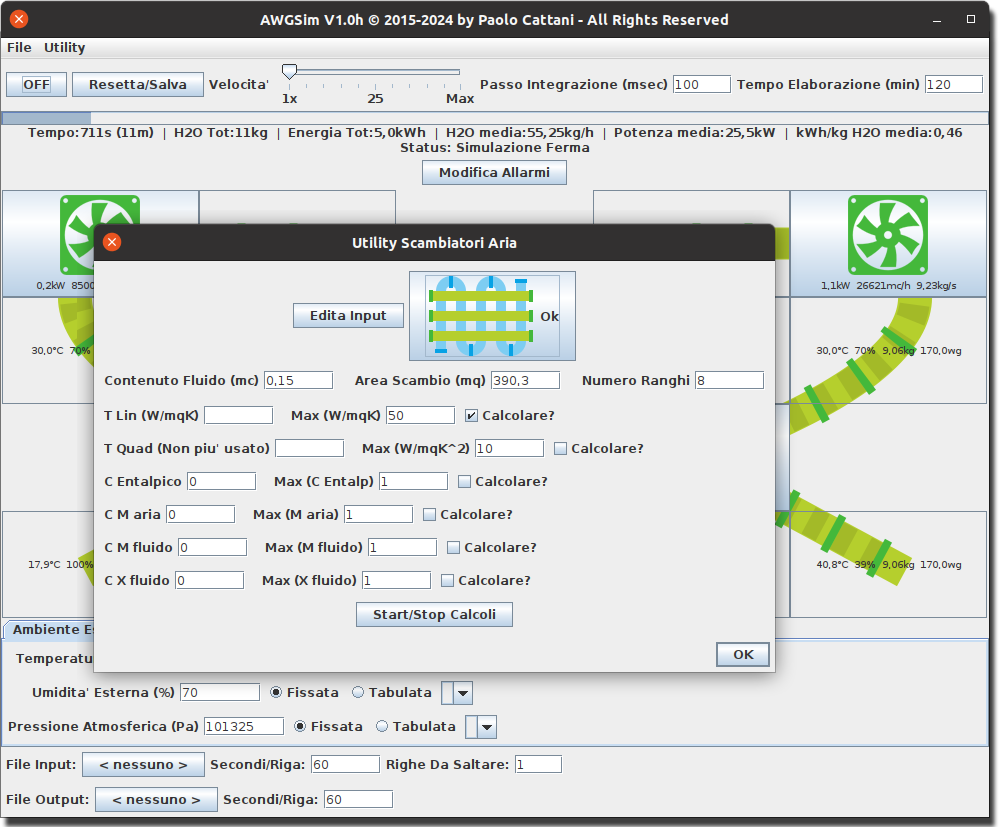

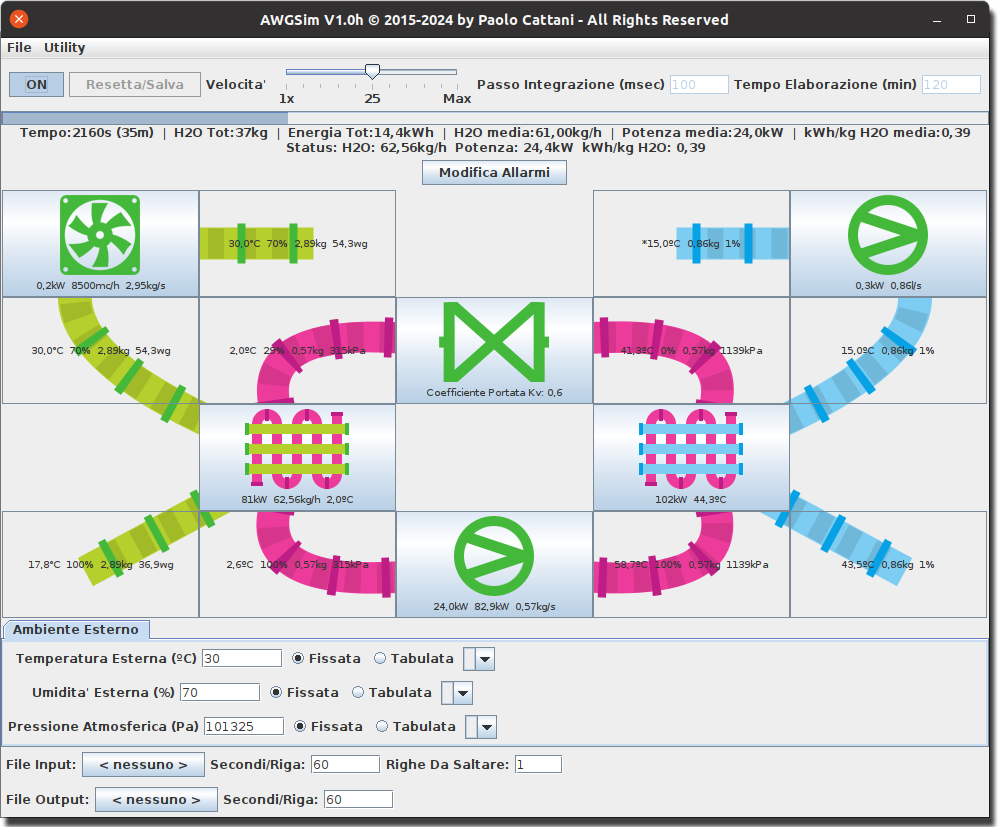

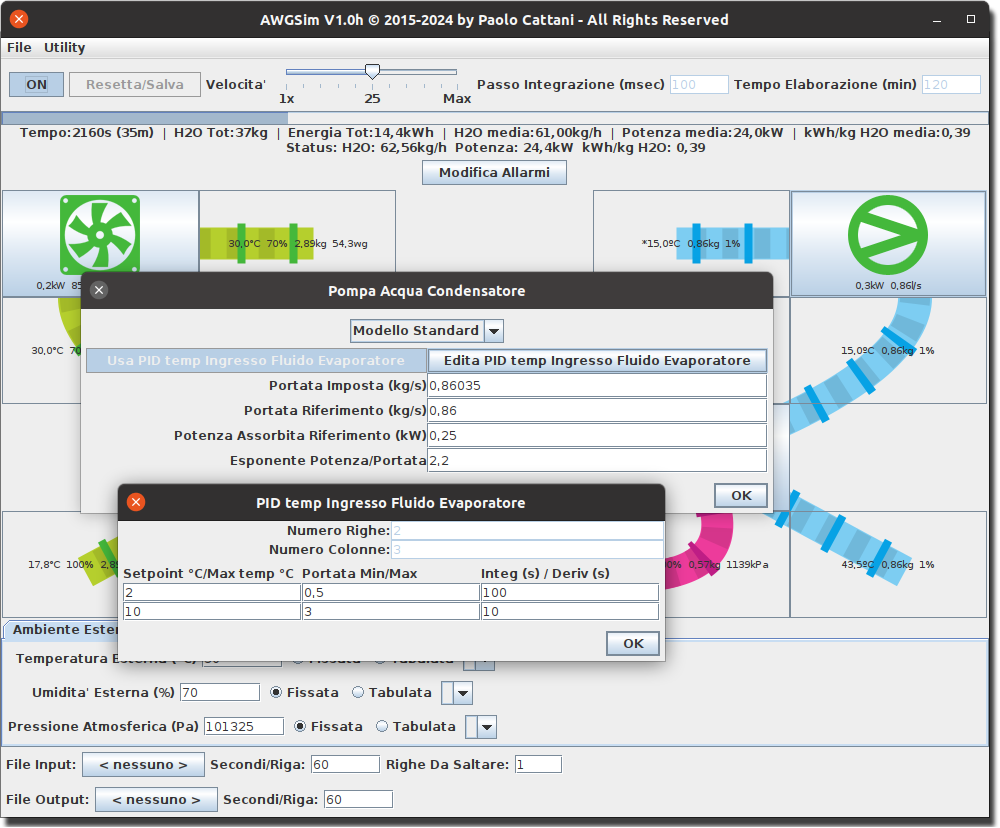

Real-time Simulation: the behaviour of an AWG is carried on through a real-time computation of mass propagation and heat exchange of the different fluids flowing in and out of the various components of the system. The simulation enforces the conservation of mass and energy, but without any additional constraint apart from those represented by real-life components; this way it is possible to reproduce the transient behaviour of the machine. AWGSim allows the user to integrate PID-based controllers in the simulation, too, in order to study the system stability or its actual response to external condition changes.

Visual Interface: AWGSim gives a visual representation of the system configuration, showing a real-time animation of fluids flowing through the components of the machine in order to immediately understand at a glance the system working. Moreover, the GUI allows the user to interact with the software, in order to stop/restart the simulation at any time, to choose the time-step, to accelerate time to get immediately to the steady state condition, and to modify the characteristics of any component at any time by clicking on its icon. Modified configurations can be saved/loaded as .xls files.

Component Library: apart from the basic components of a VCRC machine (compressors, condensers, evaporators) AWGSim can simulate many others, including heat exchangers based on different fluid types (air, water, refrigerants), pumps, fans, and so on. The library allows the user to simulate a wide variety of machines, from simple direct expansion systems to complex unit based on networks of interlinked components and fluid ducts. It is possible to use AWGSim to simulate not only AWGs, but also integrated machines that can reuse the generated cool and heat fluxes in HVAC plants.

Batch Processing: that feature allows AWGSim to unmanned process large amount of data in order to understand the behaviour of an AWG in a wide variety of conditions. As an example, it is possible to analyze the behaviour of an AWG system during a long period of time when external conditions (temperature, humidity) continuosly change, or to generate large bidimensional tables that, in function of temperature and humidity, represent the steady-state working points and the whole performance of a machine.

Screenshots

(Screenshots may not represent the actual version of AWGSim).

Applications and Research Impact

AWGSim is currently utilized in scientific research settings. Notably, AWGSim is integrated into the WISHeR project (Water-collection and Improvement of Sustainability in the HVAC Retrofitting), where it is employed to explore the effectiveness of AWG machines in sustainability and energy savings contexts. Additionally, the simulator has supported various scientific publications focused on atmospheric water generation and the integration of AWG machines within HVAC systems, contributing to the technical literature on energy efficiency and optimization of climate control systems.